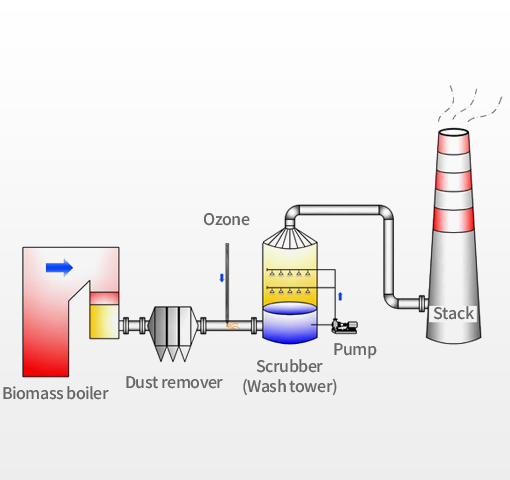

NOX / SOX Ozone treatment technology

NO and SO2 are oxidized, by adding ozone, into highly soluble oxides (NO2, N2O3, N2O5, SO3 etc.) which can be treated by wet scrubbers

| Scheme | Relative reaction rate | |||

|---|---|---|---|---|

| NO + O3 → NO2 + O2 | 62780 | fast | ||

| 2NO2 + O3 → N2O5 + O2 | 135 | little fast | ||

| SO2 + O3 → SO3 + O2 | 8 | slow | ||

| CO + O3 → CO2 + O2 | 1 | very slow | ||

| Substance | NO | NO2 | SO2 | N2O5 |

| Solubility(25℃) | 0.063 | 1.26 | 126 | >126 |

| Item | SCR | SNCR | Ozone |

|---|---|---|---|

| Installation scale | Renovating the exhaust gas piping Add SCR reactor | Modification of piping inside the incineration facility. Increased ammonia/urea injection piping |

Only one exhaust gas pipe is renovated |

| Impact on incineration facility | No effect on incineration facilities | Incineration facility in case of trouble. Stop and check |

No effect on incineration facilities |

| Installation period | Relatively long | Relatively long | Relatively short |

| Operation risk evaluation | Catalyst poisoning during driving, presence of ammonia leaks, ets. | Blockage of urea gun, rupture of pipe, presence of ammonia leaks, ets. | After the reaction, the residual gas is oxygen no additional pollution due to secondary conversion |

| Treatment efficiency | 80~90% | 40~60% | 80~95% |

본 홈페이지에 게시된 이메일 주소가 전자우편 수집 프로그램이나 그 밖의 기술적 장치를 이용하여 무단으로 수집되는 것을 거부하며, 이를 위반시 정보통신망법에 의해 형사처벌됨을 유념하시기 바랍니다 .

※ 정보통신망 이용촉진 및 정보보호 등에 관한 법률

* 제 50조의 2 (전자우편주소의 무단 수집행위 등 금지)

* 제74조 (벌칙) 다음 각호의 1에 해당하는 자는 1천만원 이하의 벌금에 처한다.